Factory Automation

Inlineworks

![]()

![]() Factory Automation

Factory Automation![]() Inlineworks

Inlineworks

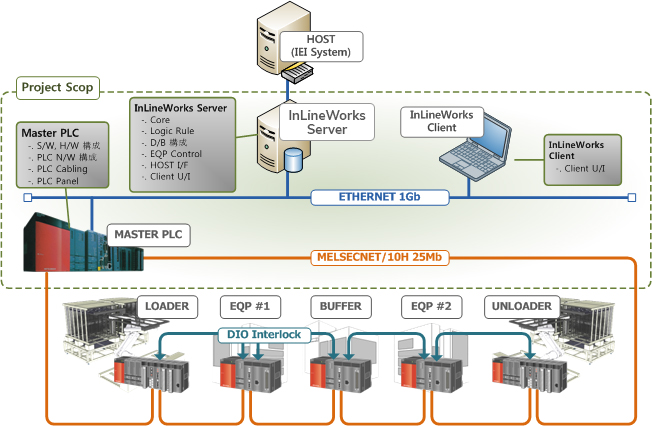

It builds Inline Controller System so that a non-stop system can be built to make a systematic and consistent system by establishing a plan that meet the needs of internal and external users.

Overall Work-Scope

- Final Spec Meeting

- Requirement Analysis

- PLC System Configuration (H/W, S/W)

- PLC Network Line Configuration

- H/W & S/W Design

- Assembling PLC Panel

- Programming

- PLC Network Cabling

- Implementation

- Unit Test

- Integration

- Acceptance

InLineWorks Architecture

Solution Benefit

-

InLineWorks System

- Fast In-Line Control System

- Standardization of Inline Control System in line

- Flexible response depends on user's business needs

- Support Engineering Data Collection for EDA System

- Support SECS for Host I/F and usable with 3rd party I/F(MSMQ) module.

- Detailed security management and powerful emergency function.

- Improve efficiency of Inline by applying optimal return logic.

-

MELSEC PLC

- Supports large-scale process information and real-time data for engineering purposes.

- Master PLC has already been verified in domestic and overseas.

- Shorten the period of development and setup by easier response of equipment makers.

- Stable and simple system.

- When an event occurs using the On Demand Event method, it is possible to collect concise data by reading the corresponding Memory Map.

- Factory Automation

- Eiworks

- MCSworks

- Inlineworks

- ISWT / ISW

- MES

- NEOSLON

- UiPath RPA

- UiPath RPA

- HyperAutomation

- IT Infra.

- HP Products & Solution

- MicroFocus

- Company

- About Us

- Our Story

- Contact Us

- Locations

- Guide

- Sitemap

- Contact Us

-

- T.+82-31-713-4871~2

- F.+82-31-713-4873